A national high-tech enterprise specializing in the research and development, production, and sales of light-emitting diode products

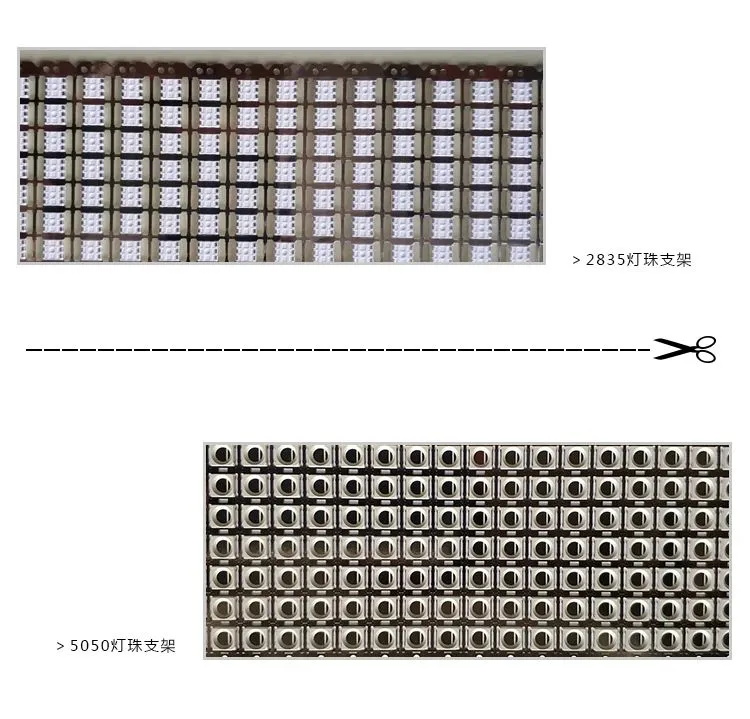

This issue will take you to understand the composition materials and production process of XINGLIGHT TOP LED (taking 2835 and 5050 as examples).

1. Package shape

The main package shape of TOP LED is shown in the figure below;

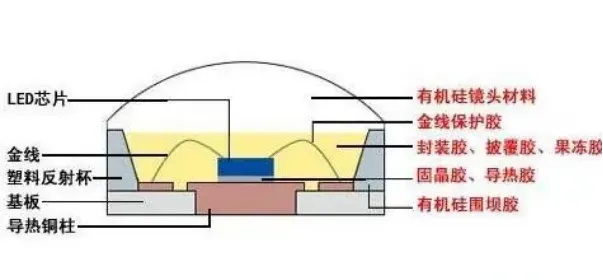

2. TOP LED structure

It is mainly composed of bracket (substrate, thermal conductive copper column, plastic reflective cup), chip, gold wire, solid crystal glue (insulating glue, silver glue), filling silicone, lens glue (ball head material), etc.

The positive and negative pins of the bracket are connected to the positive and negative poles of the power supply; the plastic reflective cup has a notch to indicate the positive and negative poles.

The shape of the colloid is usually flat and ball-shaped.

3. Main materials of TOP LED SMD lamp beads

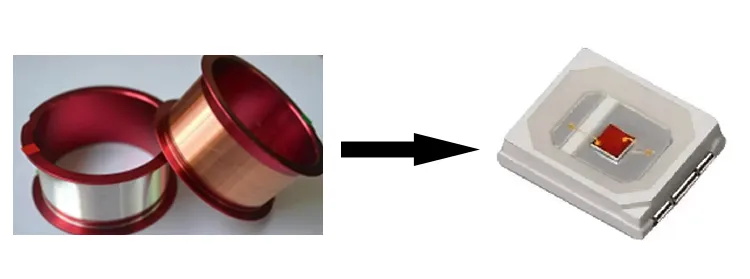

Mainly composed of PCB, chip, silver glue (insulating glue), gold wire (alloy wire), epoxy resin, phosphor and other materials. The role of the bracket inside is to conduct electricity and heat dissipation. The bracket is composed of PVC iron material or PVC copper material, with gold or silver plating on the surface. The material from inside to outside is iron or copper, nickel layer, silver layer or gold layer.

The LED chip (chip) is composed of materials such as gallium phosphide (GaP), gallium aluminum arsenide (GaAlAs) or gallium arsenide (GaAs), gallium nitride (GaN), and its internal structure has unidirectional conductivity.

Gold wire (alloy wire)

It connects the PAD of the chip with the copper foil of the PCB, and the positive and negative electrodes of the PCB copper foil and the chip are connected.

Silicone

Protect the gold wire, chip, and phosphor inside the lamp bead; dissipate heat and conduct and diffuse light.

Phosphor

The function of phosphor is to convert the blue light chip into white light; using different phosphor ratios will result in different color temperatures, different color rendering indexes, and white light of different spectra. Phosphors include YAG series, silicates, aluminates, nitrides and other different material types. Phosphors usually include red powder, yellow powder, green powder, coarse powder, fine powder, high-rendering red powder, ordinary red powder, etc.

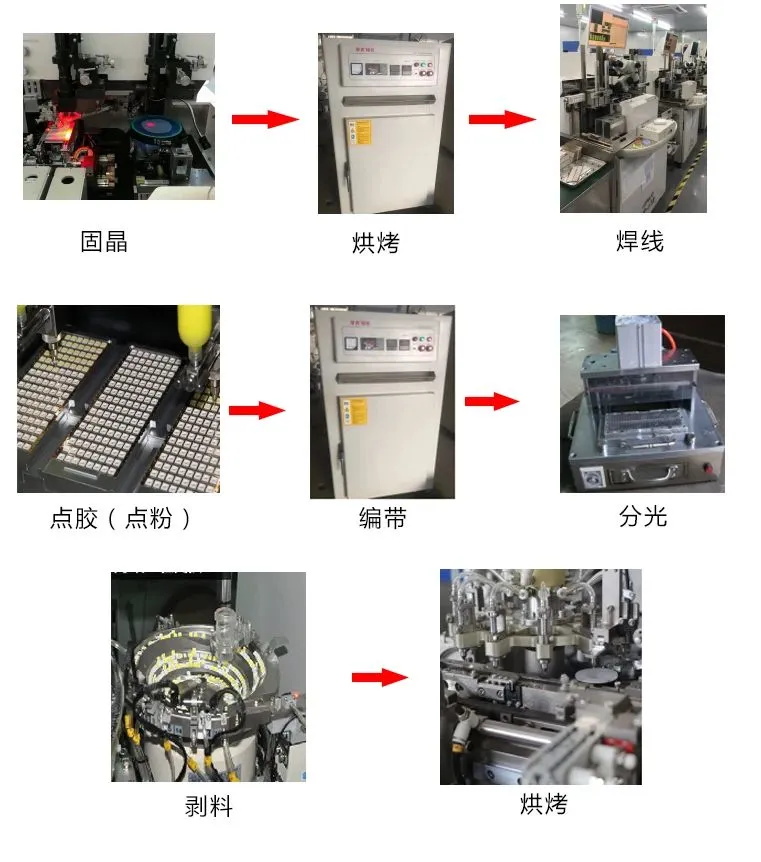

4.TOP LED production process

5.TOP LED product application

Tips

Common adverse phenomena of TOP LED

1. Color deviation is also called color difference

(refers to the error between the white light emitted by the LED and the standard color temperature, and the error value is greater than 10%). The reason is poor heat dissipation, which makes the junction temperature of the LED lamp beads too high;

The phosphor is not evenly applied, and the color temperature of the thick coating is low and it is easy to turn yellow; the quality of the phosphor glue is not good, and the high temperature discoloration causes color deviation.

2. Light flash (stroboscopic)

The cause is unstable driving power supply;

The welding wire is pressed too much or too little, resulting in loose welding wire and broken wire;

The lamp bead is damp and then reflowed, resulting in disconnection of the circuit.

3. High light decay

(After the LED is used for a certain period of time, the luminous flux is significantly less than the luminous flux before use, and the ratio of the two is less than 0.9),

The cause is poor heat dissipation, long-term overheating causes aging of LED lamp beads; the quality of phosphor glue is poor and high temperature discoloration causes color deviation.

4. Chip failure (dead lamp)

The lamp bead is damp and then reflowed, resulting in disconnection of the circuit;

The chip itself has quality problems (cracks or damage);

The chip is poorly bonded to the substrate, causing severe light decay or thermal overstress failure of the dead lamp, and poor heat dissipation leads to increased junction temperature;

Electrical overstress failure, overcurrent or static electricity breaks down the chip; unstable driving power supply burns the gold wire;

Assembly failure, poor installation and assembly lead to device failure.

5. Bubbles, black spots, corrosion, glue creeping, yellowing and other phenomena in the lamp beads

Improper packaging process, poor quality of the encapsulated lamp beads.

The above is the content of this issue. If you are interested, you can also follow us to learn more~